9kw ATC spindle motor The 9kw ATC (Automatic Tool Change) spindle motor is a high-performance motor commonly used in CNC (Computer Numerical Control) machines. With its 9-kilowatt power rating, the motor provides substantial power for various machining operations. Key Features of the 9kw ATC Spindle Motor: By incorporating the 9kw ATC spindle motor into your […]

Tag Archives: atc spindle motor

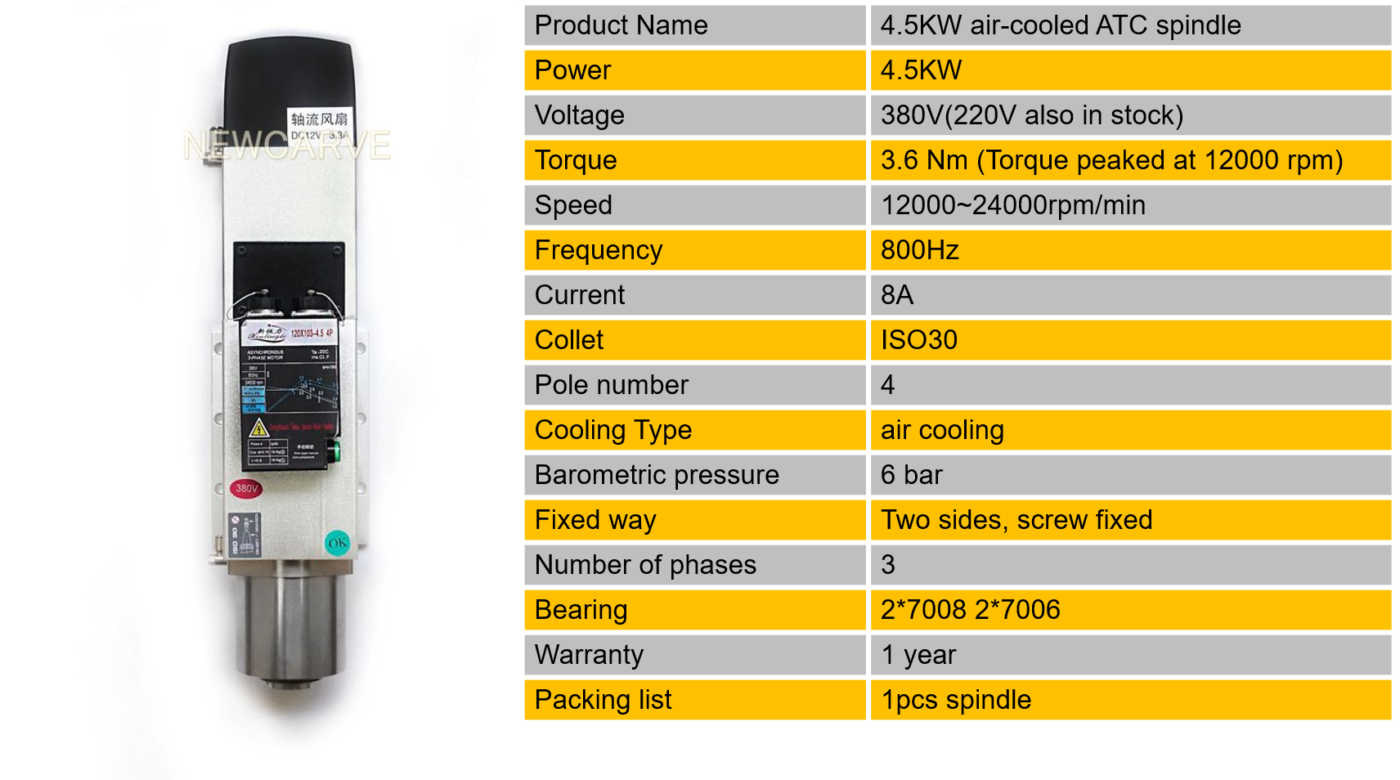

4.5kw air-cooled automatic tool change spindle is a high-end woodworking company designed to develop high-power electric spindle bearings imported from Germany, high-precision bearings, high precision, long life. The electric spindle fan cooling with Road gas seal structure, automatic tool changer with ISO30 shank, fast automatic tool changes and improves the efficiency of automated processing.

The greater the power of the electric spindle of the engraving machine, the better?

Generally, the disc type ATC wood machine center is a multi-function numerical control equipment for professional door panel processing.

One of the most important factors before choosing an automatic tool change spindle is what type of material you want to engrave.

The following are some common treatments for tool magazine failures. Of course, these are not absolute and need to be applied in specific situations.

In fact, slight rust does not affect the normal use of the ATC spindle motor. However, if this is the case for a long time, the life of the spindle motor will be shortened.

There is a trend now that manufacturers are thinking about how to improve their productivity.

n fact, there are many types of tool holders available for use in the CNC shop. And the two most common types are V-type flange holders and BT-type flange holders.

The tool systems typically include a shank that connects the ATC spindle, a medium indirect rod, and a tool. Also, more complex tooling systems include accessories such as extension rods, reducer sleeves, and tool attachment handles. We generally apply these in machining centers.