Common fault analysis and correct handling of automatic tool change spindle motor and high-speed motor:

Tag Archives: 9kw atc spindle

High-quality automatic tool change spindles and related accessories!!

the built-in motor and the rolling bearing generate a large amount of heat during the rotation. Moreover…

In order to ensure better machining quality and extend the life of the tool and the ATC spindle, it is necessary to minimize the vibration.

Before troubleshooting the ATC spindle, let’s take a closer look at the entire sequence of the tool change.

However, there are still some signs that may cause us to warn that the spindle may malfunction.

As an operator, you should understand the principles of spindle machining applications and operations.

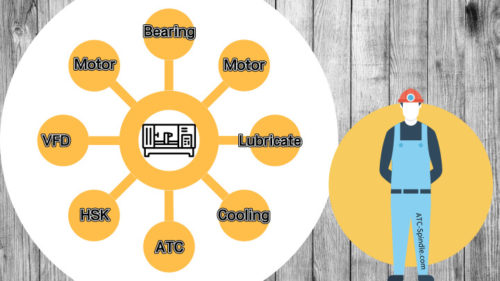

The spindle is designed according to the application and user specifications. But no matter what type of machine you use, the spindle is the core part of the machine’s operation.

It will reduce the performance of the tool by scratching the part. Even more frightening is that this may also threaten the safety of operators.

The structural layout of the spindle motor that can not be ignored by people engaged in woodworking carving work: