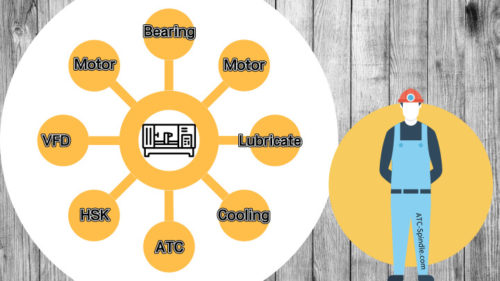

The structural layout of the spindle motor that can not be ignored by people engaged in woodworking carving work:

1.High-speed bearing

Spindle motors are usually made of composite ceramic bearings that are wear resistant and heat resistant. But life is several times that of conventional bearings. And sometimes electromagnetic suspension bearings or hydrostatic bearings are used, and the inner and outer rings are not in contact. So the life span is infinite in theory.

2. High-speed motor

The spindle motor is the product of the motor and the spindle. And the rotor of the motor is the rotating part of the spindle. In theory, the spindle motor can be regarded as a high-speed motor. Therefore, the key technology is the dynamic balance at high speed.

3. Lubricate

The lubrication of the spindle motor is generally based on timed quantitative oil and gas lubrication. Oil quantity control is very important. If the amount of oil is too small, it will not be lubricated. If the amount of oil is too high, and it will heat up due to the resistance of the oil when the bearing rotates at a high speed.

4. Cooling device

In order to dissipate heat from a high-speed spindle motor as quickly as possible, the outer wall of the spindle motor is usually circulated with coolant. The function of the cooling device is to maintain the temperature of the coolant.

5. Built-in pulse encoder

In order to achieve automatic tool change and rigid tapping, the spindle motor has a built-in pulse encoder for accurate phase angle control and coordination with feed.

6. Automatic tool changer

In order to be applied to the machining center, the spindle motor is equipped with an automatic tool changer, including a butterfly spring and a broach cylinder.

7. The high-speed tool loading method

The well-known BT and ISO tools have been proven to be less suitable for high-speed machining. Therefore, high-speed tools such as HSK and SKI have appeared.

8. High-Frequency Converter

In order to achieve a speed of tens of thousands or even hundreds of thousands of revolutions per minute of the spindle motor, a high-frequency inverter must be used to drive the built-in high-speed motor of the spindle motor. The output frequency of the inverter is up to thousands or several kilohertz. In addition to providing expertise in woodworking engraving machines, ATC-Spindle.com offers a more cost-effective ATC spindle.