9KW ATC Spindle Motor HQD GDL70-24Z/9.0

The 9KW ATC Air Cooled Spindle, model HQD GDL70-24Z/9.0 Long Nose/Short Nose, is a high-quality motor designed for automatic tool changing applications. With a power rating of 9KW, it delivers reliable performance. This spindle moto, operates on both 220V and 380V power supplies, making it versatile for various CNC machining tasks.

Product Description

| Spindle Type | GDL70-24Z/9.0 | Brand | HQD |

| Power | 9Kw | Joint of nose | ISO30 |

| Voltage | 380V/220V | Cooling | by fan |

| Current | 20A/32A | Bearings | 2pcs*7008C/P4,2pcs*7006C/P4 |

| Speed | 24000rpm | Net weight | 31kg/26kg |

| Frequency | 800Hz | Poles | 4P |

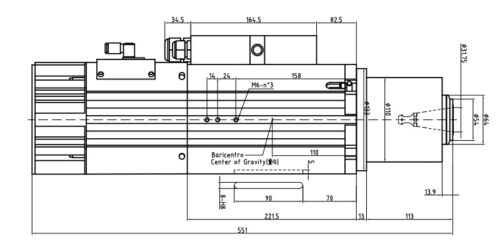

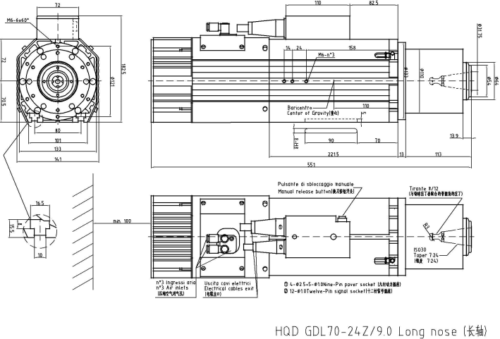

long nose drawing

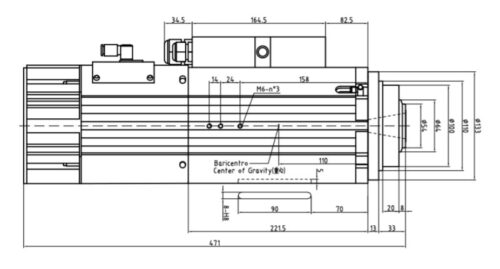

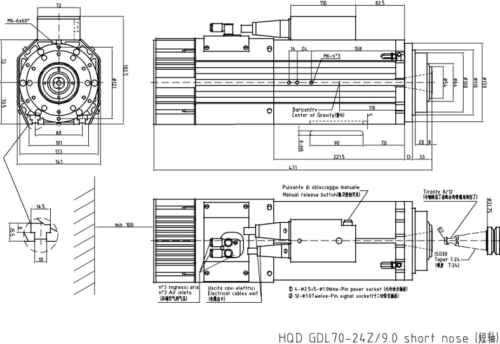

short nose drawing

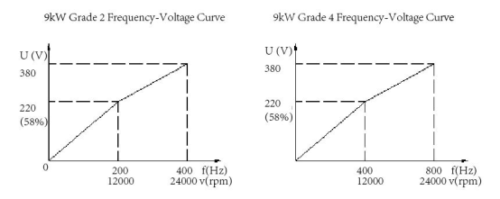

Frequency-Voltage Curve

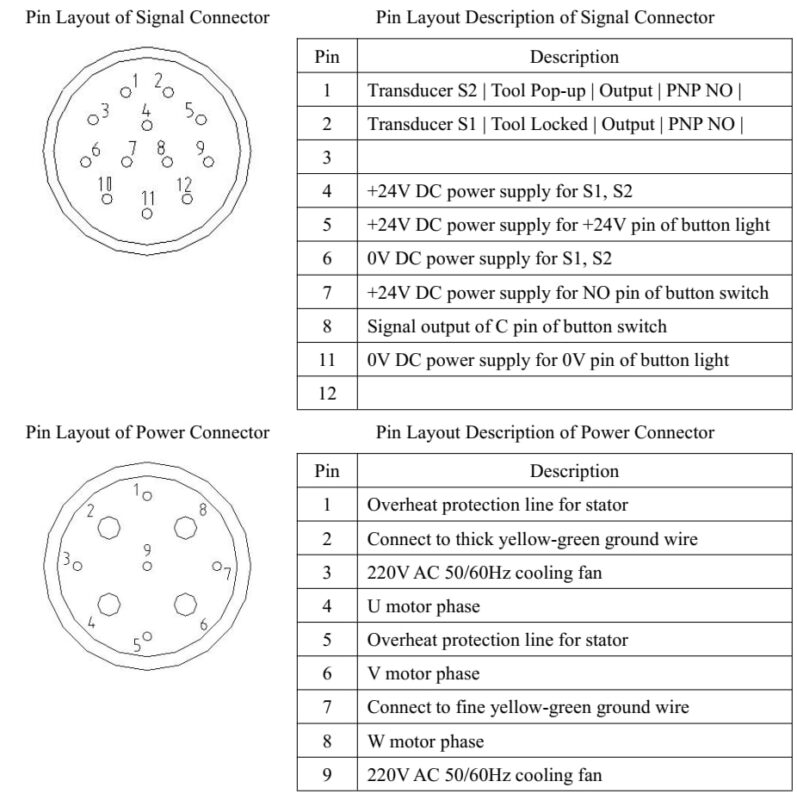

Pin Layout

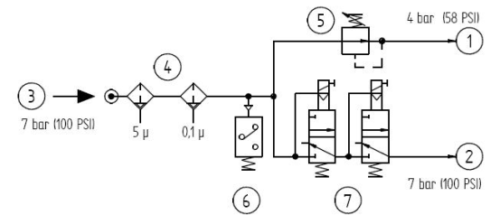

Functional diagram for the connection of compressed air of electrical spindle

This picture presents the typical connection of compressed air system, and the system shall be prepared by customer. Apply two solenoid valves to decrease the risk of system failures. Although this kind of failures happened rarely, once it happens, it may cause serious consequences; therefore, it is recommended to provide redundancy.

| 1 | Inlet of cone cleaning and internal pressurization (please refer to N°1 in figure9.5 at the same time). |

| 2 | Inlet for release of tool holder(please refer to N°2 in figure 9.5 at the same time). |

| 3 | Inlet of air sourceof factory |

| 4 | Filtering and dryingset of compressed air with automatic drainage of condensate water: 5μ for the first phase,and 0.1μ for the secondphase; |

| 5 | 4 bar pressure regulator (58 PSI) |

| 6 | Pressure switch |

| 7 | A pair of three-way mono-stable solenoid valve |

- Apply two separate loops to connect the solenoid valves (position of ref.7 in figure 9.6) to numerical control unit or manual control system.

- Important notice: air source of compressed air shall be dry and filtered.

- When the machine is running, and the electrical spindle has stopped, it shall provide compressedair at any time to avoid the dust and dirt from machining area entering into the electrical spindle(please refer to item 7.7.3).

- When electrical spindle has stopped, make sure there is steady air flow (compressed air) aroundelectrical spindle. Otherwise, please check the air loop and its connection.