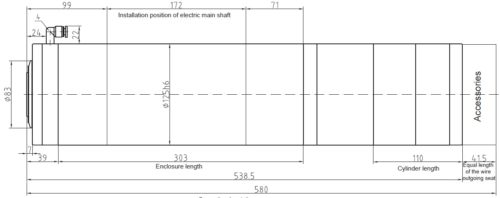

| Model | GDL125-40-12Z-7.5 |

| Voltage | 380V |

| Power | 7.5 KW |

| Current | 16.5 A |

| Torque | 5.98Nm |

| Frequency | 600 Hz |

| Rotating speed | 12000 rpm |

| Cooling | Water cooling |

| Lubrication | Grease |

| Bearing No. | 2*SM6011C/P4,2*7008C/P4 |

| Pole number | 6P |

| Phase number | 3 |

| Rotating direction | Rotate anticlockwise from the shaft extension end |

| Tool holder | BT40 (Parfaite is recommended) |

| Blind rivet | BT40-45° (Parfaite is recommended) |

| Weight | 35 KG |

Connection requirements

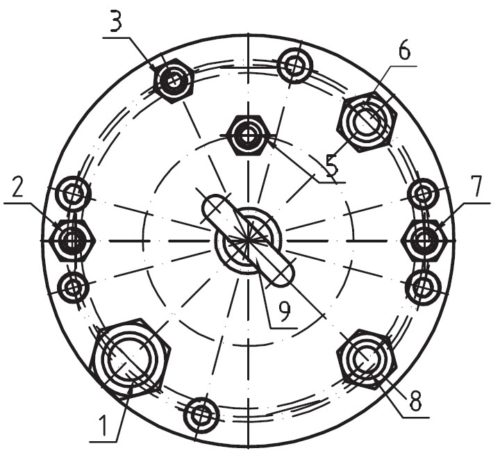

1. Power line: Three-color power line and yellow-green earthing line. Temperature control line 110°C thermistor two-piece fine wires 2. Cooling: effluent 3. Tool changing/dust removal pressure: 0.2MPa 4. Air seal pressure: 0.1-0.2MPa 5. Tool discharge and air feed pressure: 0.70MPa 6. Encoder voltage: 5VDC 7. Cooling water feed: Pump lift 12m 8. Proximity switch: for tool discharge and hanging NPN (normally open) N. O. 9: Handle of the lifting

Connection description

1. Three-color power line connected with U, V and W phases of a frequency converter, and the yellow-green wire connected with the earth wire. Temperature control line connected with the temperature control protector 2. Rapid inserted connecting pipe for the cooling effluent is 8/6 hoses 3. Rapid inserted connecting pipe for the cooling effluent is 6/4 hoses 4. Rapid inserted connecting pipe for the air seal is 4/2 hoses 5. Rapid inserted connecting pipe for the tool discharge and air feed is 6/4 hoses 6. Encoder voltage: 5VDC 7. Rapid inserted connecting pipe for the cooling influent is 8/6 hoses 8. Brown wire of the proximity switch connected with +24VDC Blue wire connected with 0VDC 9. Installation and use of the handle of the lifting sling

| PTC single-core thermistor parameter | |

| DC power supply | Maximum DC25V/100mA |

| ‘-20~25℃ | ≤300Ω |

| ≤90℃ | ≤750Ω |

| 105℃ | ≤1650Ω |

| 110℃ | Rated operating temperature |

| 115℃ | ≤3990Ω |

| ≥125℃ | ≤12KΩ |

| ≤160℃ | Maximum storage temperature |

Special warning:

- The electric main shaft shall be installed at the clamped position; otherwise, the bearing will be easily damaged!

- The main shaft shall entirely stop before the tool changing. The manual tool changing button shall not act during the rotation of the shaft; otherwise, it will easily result in the seizure of the shaft!

-

The compressed air shall be clean and dry, and the filter accuracy shall be 0.1micron! The air seal is normally open. It is recommended to use the two-level filter, and the filter accuracy is 0.5 micron/ 0.1 micron respectively. The air filter is installed with the self-discharge device.